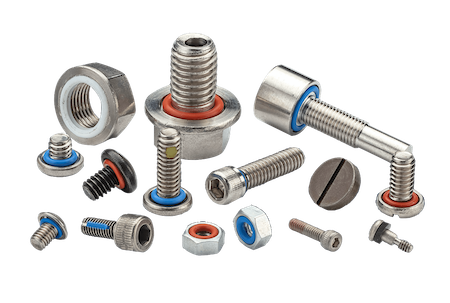

Thanks to that patented design, our solutionsensure perfect protection and sealing for your systems. This system integrates a O-ring

silicone in a groove machined under the head of the screw. It is compressed inside the bore

and not between the screw head and the contact surface.

When tightening, direct contact between the screw head and the support is therefore maintained. Without this groove, the O-ring would not ensure a good seal, it would be compressed (or damaged) by the screw head on the contact surface and would be irreparably damaged.

This new system has been designed not to compress the joint by more than 20%, thus guaranteeing better hold and lifetime

increased.

This also allows several reuse

of the screw/gasket assembly without the risk of forgetting the gasket or reusing a damaged gasket during maintenance operations.

This technology adapts to all screws from M2 and depending on the screw head (Cruciform, CHC, Hexagonal, countersunk, etc.).

Elastomer production is one of the fastest growing areas of manufacturing and there are over 20 different types of elastomers that serve different functions both in manufacturing processes and in the finished products themselves.

The type of elastomer affects the physical properties, functions and lifespan of your parts. Therefore, it is important to test different elastomers when assembling your product to determine which one best suits your needs.

Here we offer you a practical guide to the different types of elastomers used as well as some of their most common applications.

- Silicone

- Fluoro-silicone

- Neoprene

- Buna N (Nitrile)

- Fluorocarbon (Viton®)

- EPDM (ethylene-propylene-diene monomer)

Leave us a comment and we will get back to you!